Proportions into large stocks. Br r-RR - 1º step.

Ribbon Blender Ribbon Mixer Design Calculation And Selection

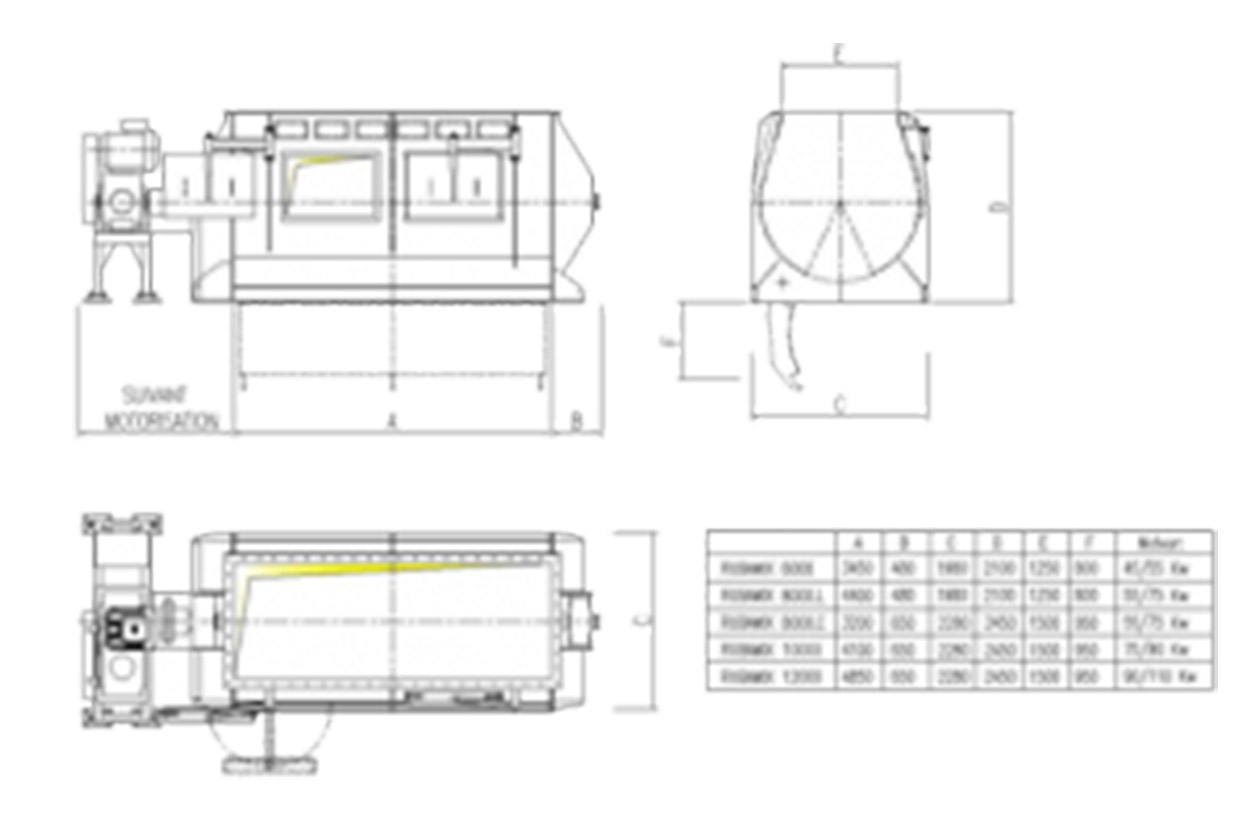

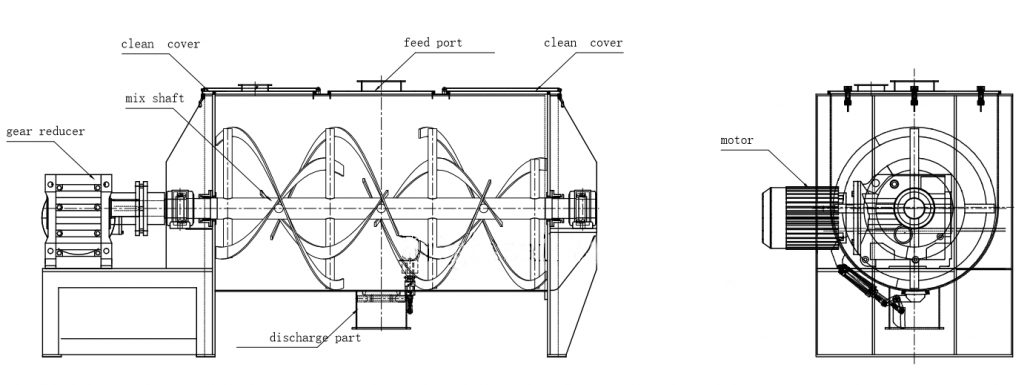

The volume and profile of the ribbon blender are the most important aspects to consider when selecting your ribbon blender.

. Now developed the outside diameter. Equipped with a liquid-tight flush valve Ribbon Blenders built for this type of application can include jacketing around the trough to control product temperature. Ribbon blender requires that the batch size the material volume in the vessel be equivalent to at least 30 to 40 percent of the blenders rated volumetric capacity.

The desired batch volume determines the size of the blender but product bulk density determines if a standard or heavy-duty model is required. Al-though mixer design begins with a focus on process requirements the mechanical design is essential for successful operation. Radial movement is achieved because of the rotational motion of the ribbons.

The ribbon blender is one of the most versatile and commonly used blender in the chemical pharmaceutical and food industries. Performances of Dry solid powder mixing with in a twin Ribbon blade blender have been performed in this work in order to characterize mixing behavior in such a mixer of binary mixtures with different cohesionless materials. If you are producing different blends in one blender Continued.

Need A Mixer Contact. The ability of this blender to handle solids of different size ranges bulk densities and other ingredient characteristics combined with the possibility of heating cooling drying and coating of solid particles makes its a very popular. 21-1 INTRODUCTION Mixing equipment must be designed for mechanical and process operation.

Ribbon Blender is primarily designed for use with dry materials although gas and liquid streams can also be introduced. Click here to see a ribbon blender in action. More robust blenders are available for denser products.

When the level matches the shaft of the ribbon 59 the maximum height of the inner blade 86 and the height of the outer blade 100. However some basic information and general rules may be sufficient to give direction for this designIn general these densities are at the moderately high end of powder properties handled in ribbon. Working The outer ribbons of the agitator move the material from the ends to the center while the inner ribbons move the material from the center to ends.

In some cases a very large blender might be suitable. Drive design choices Traditional ribbon blenders utilize a belt drive for power transmission between the motor and gear reducer. Tip speeds in the range of 300 feetmin are typical.

Examples include ready-to-eat soups pasta sauces pet food and the like. Ribbons and support arms are clean and effi cient. To answer all of these questions with associated calculations is not a simple task since the mixer design involves many variables and design decisions.

R R-b bR-r. All limit switches must be wired into the motor control circuit to disconnect power All stainless steel construction when the grates are removed or the covers opened depending on the blender design. Rec- ommended turndown ratio will be confirmed by the blender supplier.

The difference in the peripheral speeds of the outer and inner ribbons results in axial movement of the material along the horizontal. This combination promotes fast and thorough blending. The effects of fill height and blade rotation speed on mixing homogeneity have been studied.

The drive system includes fl exible belts and a set of pulleys to produce the desired speed and torque ranges. Usually a competent manufacturer of. For example if a blend comprises of 25 of ingredient A having bulk density of 500 kgm3 and 75 of ingredient B having bulk density of 1000 kgm3 the average bulk density should be calculated as follows.

The effect of fill level is tested for a blender with a 5-spoke blade operated at 20 rpm loaded with magnesium stearate in a. This will depend on the amount of material you are mixing as well as the speed with which it must be mixed. Design considerations had been studied during Analytical.

B square root of PId2 P2. Feeding through a hopper mounted on top of blender. Unique Mixers Furnaces Pvt LtdContact Person.

Mechanical Design of Mixing Equipment D. A square root of PID2 P2. Fill your blender properly.

A wide variety of configurations for either batch or continuous mixing are available. Abbe designs and manufactures ribbon blenders which are ideal for blending dry free-flowing solids with bulk densities up to 70 pounds per cubic foot 11 gcc depending on material characteristics including particle size size distribution and particle shape morphology angle of repose cohesiveness and moisture level. Mr Jayesh TekchandaneyEmail us.

Bearing mounted on lanterns outside of mixing container to avoid contamination. Calculations for Ribbon Blender So consider that b is the result of D-d2. How ribbon blenders work Ribbon blenders consist of a U-shaped horizontal trough and an agitator made up of inner and outer helical ribbons that are pitched to move material axially in opposing directions and also radially.

So the developed inside radius of the flight will be. About of Ribbon Blenders Ribbon blenders are widely used for homogeneous mixing of dry granules powders. The experiments conducted here use a ribbon blender at the three capacities mentioned above.

Average Bulk Density 025 x 500 075 x 1000 875 kgm3. Optimal mixing in a. Industry-wide most standard ribbon blenders can typically handle bulk densities of around 35 lbscuft.

Benefits of ribbon blander Sanitary design-heavy gauge stainless steel constructions. Ribbon Blenders are also utilized for mixing discrete solid pieces within a low-viscosity liquid vehicle. Application specific rotor mixing element design allows shorter batch cycle times due to increased mixing.

License Dozens Staple Calculations For Ribbon Blender Willy Huybrechts Gallery Com

Ribbon Blender Ribbon Mixer Design Calculation And Selectionsparkler Filter Press Manufacturer

Ribbon Blender Capacity Calculation Ainuok Machinery

Ribbon Blender Ribbon Mixer Design Calculation And Selectionsparkler Filter Press Manufacturer

License Dozens Staple Calculations For Ribbon Blender Willy Huybrechts Gallery Com

Ribbon Blender Ribbon Mixer Design Calculation And Selection

Ribbon Blender Ribbon Mixer Design Calculation And Selection

Feed Blending Machine For Sale Ribbon Blender Machine With High Accuracy Blenders Machine Mechanical Design Pharmacy Images

0 comments

Post a Comment